PROJECT TITLE: MULTI-PHYSICS, COUPLED ANALYSIS OF SPATIALLY TAILORED AERO-THERMAL STRUCTURES

PARTICIPANTS: CHRIS OSTOICH (PHD), MAHESH SUCHEENDRAN (PHD), PROF. DANIEL BODONY (U. ILLINOIS) AND PROF. PHILIPPE GEUBELLE

SUPPORT: AFRL AIR VEHICLES DIRECTORATE THROUGH THE MIDWEST STRUCTURAL SCIENCE CENTER

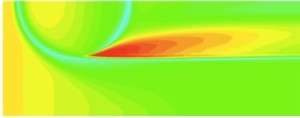

PROJECT DESCRIPTION: A high-fidelity numerical approach is used to predict the response of aerospace structures in extreme environments where coupling between fluid, thermal, and structural physics is significant. Previous work involved the prediction and comparison with experiment of the thermal response of a rigid thermal protection system geometry under a laminar boundary layer in a Mach 6.59 flow.

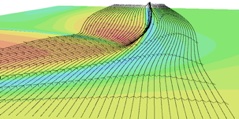

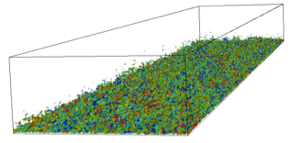

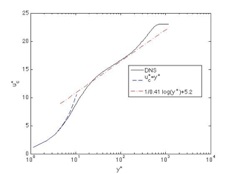

Results are shown in Figure above. Over most of the surface, an aerospace structure will be wetted with a fully turbulent boundary layer. Currently, the response of a thermally and structurally compliant panel under a Mach 2.25 turbulent boundary layer is being studied. A direct numerical simulation of the turbulent boundary layer takes place in the fluid domain in order to calculate the fluid loading and study the effect of coupling on the flow. The thermal and structural solution of the panel is found using a finite strain thermomechanical finite element code.

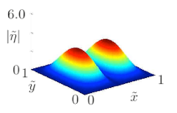

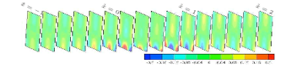

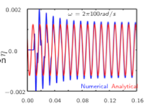

Using a high-fidelity computational approach, the panel motion is computed for the geometry shown in figure above, where 140 dB amplitude sound waves from 75-500 Hz graze a 3 mm thick Aluminum panel backed by a small cavity. To complement the numerical method, an analytical solution was formulated for the fully coupled response of the cavity-backed thin plate and compared its predictions against the numerical predictions.

The above set of results show an example for a sound wave which excites the (2,1) plate mode (left) and generates the pressure field (middle) and the measured response (right). A key aspect of the coupled response is that the panel motion generates its own pressure field that adds to the incident sound field and creates a different loading condition.

RELEVANT PUBLICATIONS:

- Ostoich, C. M., Bodony, D. J. and Geubelle, P. H. (2012) “Coupled fluid-thermal response of a spherical dome due to a Mach 6.59 laminar boundary layer.” AIAA Journal, 50:12, 2791-2808.

- Ostoich, C., Bodony, D. J., and Geubelle, P. H. (2013) “Interaction of a Mach 2.25 turbulent boundary layer with a fluttering panel using direct numerical simulation.” Physics of Fluids, 25, 110806. DOI: 10.1063/1.4819350. AIAA Fluid Dynamics 2013 Best Paper Award.

- Ostoich C., Bodony, D. J., Geubelle, P. H., « Coupled computational fluid-thermal investigation of hypersonic flow over a quilted dome surface,” Bull. Amer. Phys. Soc., Vol 54(19), 2009.

- Ostoich, C., Bodony, D. J., and Geubelle, P. H. « Development and validation of a first-principles fluid-thermal multi-physics solver for hypersonic boundary layer heat transfer problems . » AIAA Paper 2011-1964, 52nd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. April 4-7, 2011, Denver, CO.

- Ostoich, C., Bodony, D. J., and Geubelle, P. H. « Prediction of heat transfer into a thermally compliant surface in a Mach 5.73 boundary layer using direct numerical simulation. » AIAA Paper 2011-3706. 41st AIAA Fluid Dynamics Conference and Exhibit, June 27-30, 2011, Honolulu, Hawaii.

- Ostoich C., Bodony, D. J., Geubelle, P. H., ‘Aerothermal analysis of the coupled response of a panel under a supersonic turbulent flow using direct numerical simulation.’ AIAA ASM Meeting, January 2013, Dallas, TX.

- Sucheendran, M., Bodony, D. and Geubelle, P. H. (2014) “Coupled structural-acoustic response of a duct-mounted elastic plate with grazing flow.” AIAA Journal, 52:1, 178-194. DOI: http://arc.aiaa.org/doi/abs/10.2514/1.J052168.

- Sucheendran M., Bodony, D. J., Geubelle, P. H., ‘Structural-acoustic interaction of a cavity-backed, clamped, elastic plate with sound in a duct.’ Bull. Amer. Phys. Soc., Vol 54(19), 2009.

- Sucheendran, M., Bodony, D., and Geubelle, P. H. « Structural-acoustic response of a cavity-backed plate in a duct. » AIAA Paper 2011-2015, 52nd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. April 4-7, 2011, Denver, CO.

- Sucheendran, M., Bodony, D., and Geubelle, P. H. «Structural-acoustic response of an elastic plate in a duct : Comparison of theory with numerical simulation. » AIAA Paper 2011-2850, 17th AIAA/CEAS Aeroacoustics Conference (32nd AIAA Aeroacoustics Conference). June 5-8, 2011. Portland, OR.

- Sucheendran, M., Bodony, D., and Geubelle, P. H. « Coupled structural-acoustic response of a duct-mounted elastic plate with grazing flow. » AIAA Paper 2012-2169. 18th AIAA/CEAS Aeroacoustics Conference (33rd AIAA Aeroacoustics Conference). June 4-6, 2012, Colorado Springs, CO.